Skills

Analog/Mixed Signal Design

Semi/full custom transistor level design of various types of analog blocks, behavioral modeling of circuits,

layout design and floor planning, DRC and LVS analysis, FEM electromagnetic analysis,

PVT/Monte Carlo verifications, experience with industrial CMOS process (0.35um, 0.18um, 40nm, 28nm),

System level design and analysis, behavioural modeling using higher levels of abstarctions,

specifications and summery of work definition,

Solid understanding of low power design techniques, analog/digital design, microwave engineering,

solid-state and electromagnetic physics, mechanics,

Hands-on experience with lab characterization equipment, e.g. network analyzers, lock-in amplifiers,

oscilloscopes, signal generators;

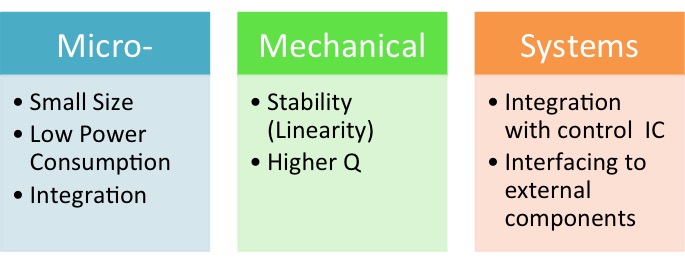

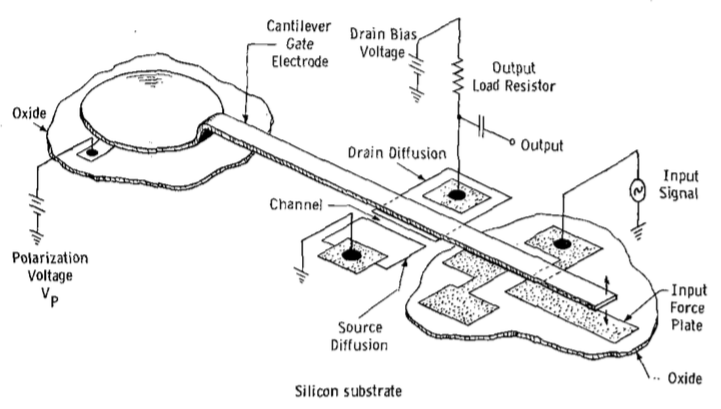

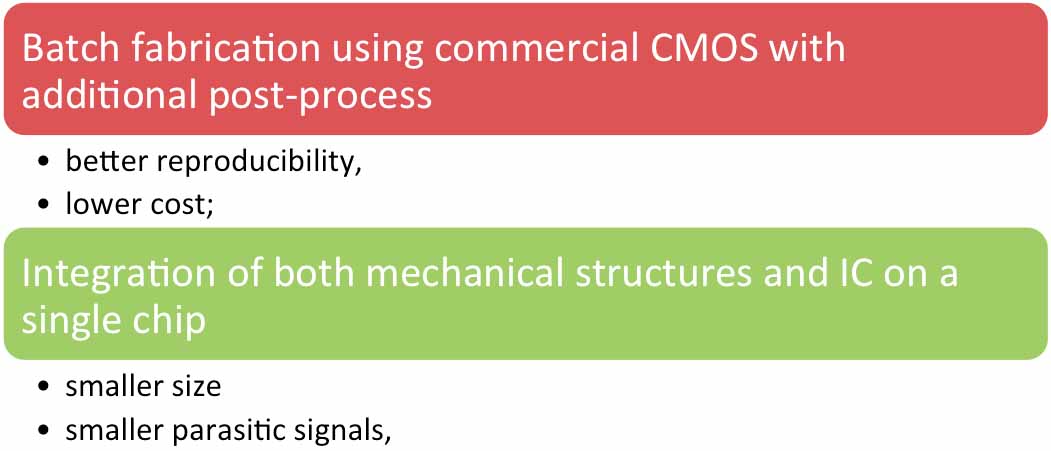

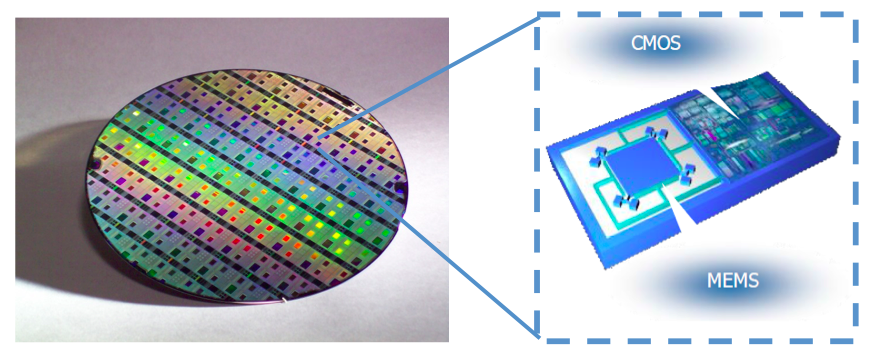

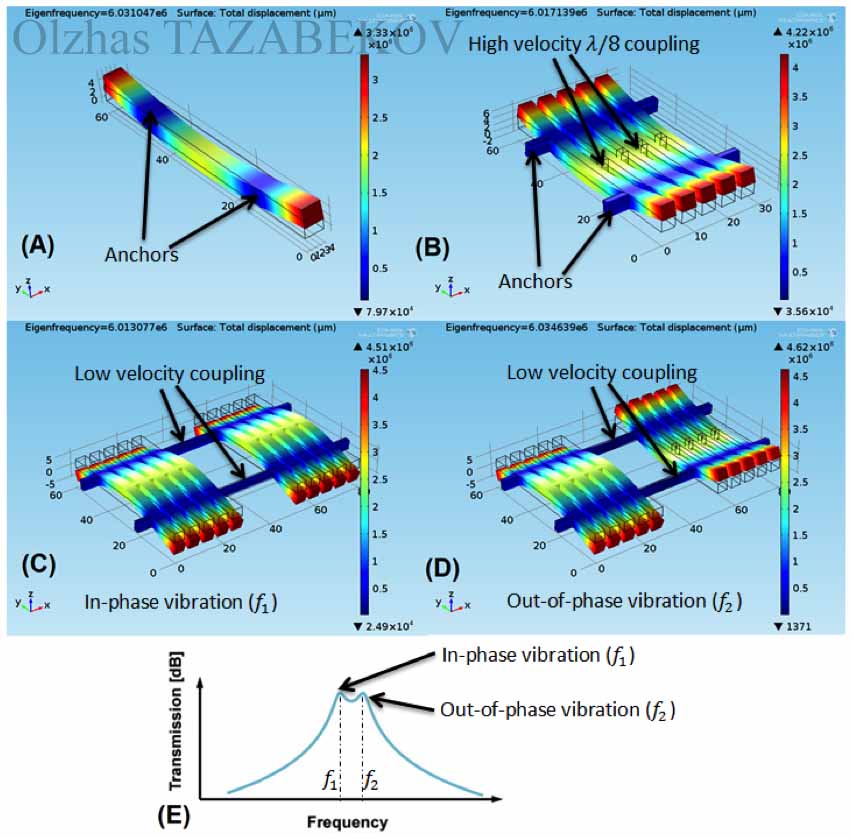

Micro-Electro-Mechanical Systems for RF and Sensors

MEMS design (electrostatically/electrothermally driven actuators and resonators),

MEMS layout design (optimization for manufacturing and CMOS compatibility),

analytical, finite element and behavioral system level modelling,

Hands-on experience with post-CMOS MEMS fabrication in a cleanroom and fabrication/characterization equipment

(reactive ion etching machine, electron and optical microscopes, doppler laser vibrometer);

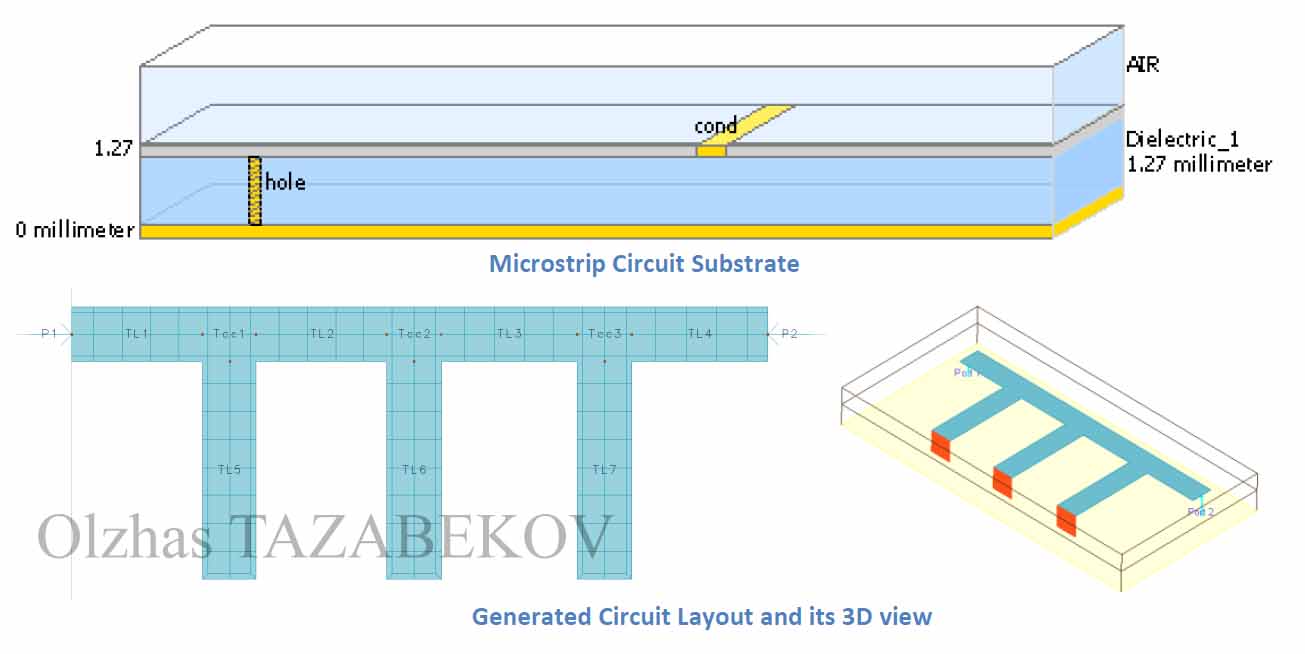

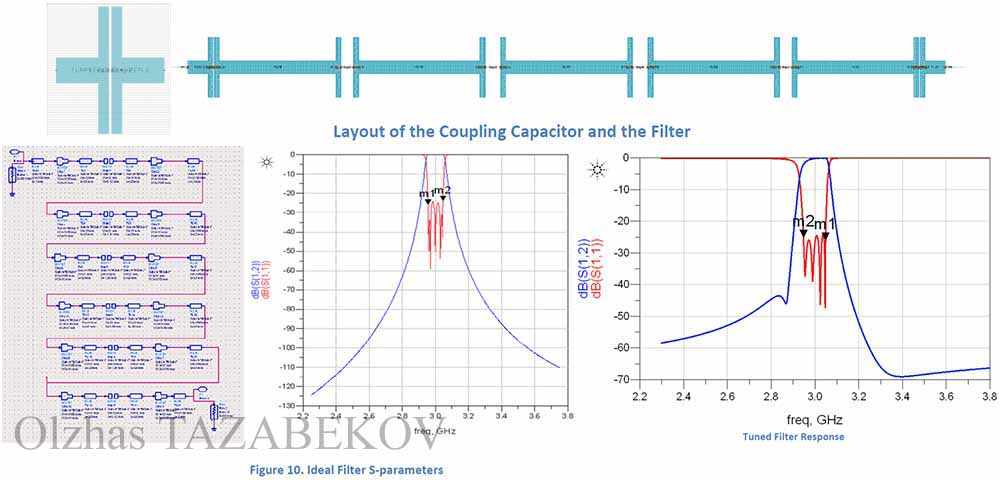

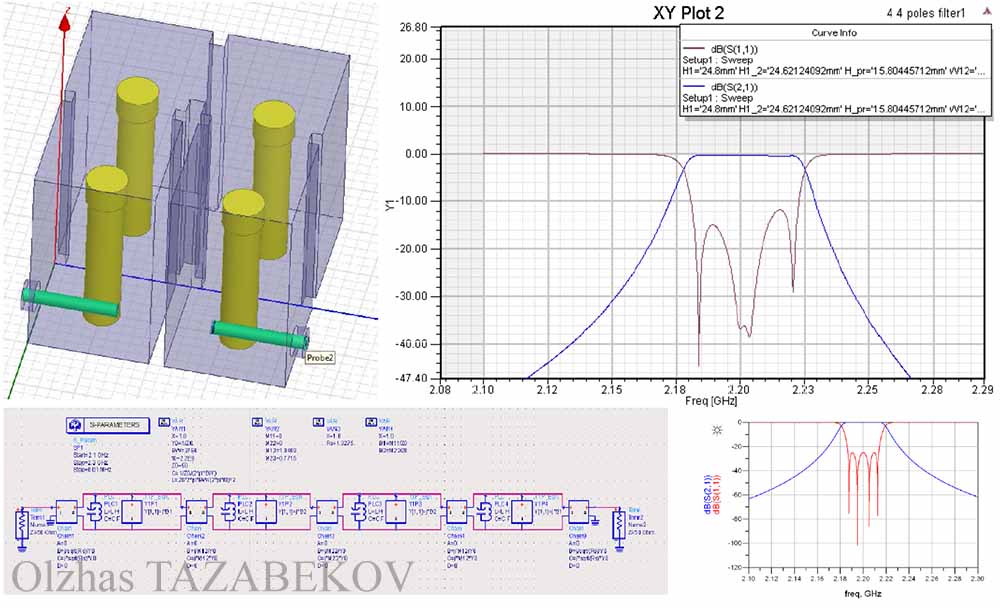

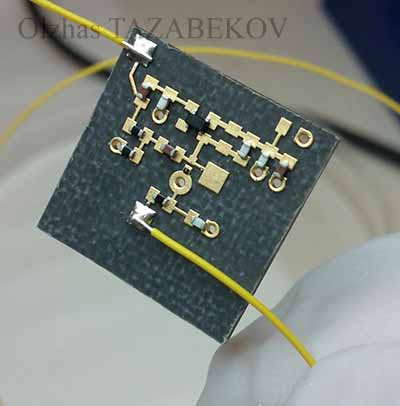

RF circuits and passive component desing (e.g. planar microstrip and cavity resonators and filters),

EM and circuit simulation, advanced filter design techniques (space mapping, recursuive extraction),

solid understanding of microwave theory;

Computational programming and behaviora modelling with Python, Matlab and Mathematica,

Solid understanding of object oriented programming, data processing and visualization,

Hands-on experience with unix-based operating systems and scripting;

IC/RF EDA Tools: Cadence IC Design suite, Synopsis IC Design suite, Agilent ADS, Xyce, NGspice,

FEM EDA Tools: ANSYS HFSS, Agilent Momentum, COMSOL, Coventor,

Numerical Computing Software: Mathematica, Matlab/Simulink, Mathcad,

PCB EDA Tools: Eagle, Altium Designer,

Programming Languages: Python, VHDL, C++, Pascal, Java, HTML;